How the UK is Building Smarter, Faster, and Cheaper

The Housing Crunch That Sparked Innovation

The UK’s housing shortage has been a stubborn problem for decades. Demand keeps climbing, yet traditional construction methods struggle to keep pace.

Brick-and-mortar building is slow, expensive, and heavily dependent on a workforce that’s already stretched thin.

In an era when cities are bursting and affordability feels like a fading dream; the industry needed a new playbook. That’s where robotics and timber come storming in.

Why Timber is Making a Comeback

For years, masonry has been the UK’s go-to method. But timber, especially in prefabricated frames, is proving itself as the faster, greener, and even cheaper option.

Studies show that offsite timber construction can cut costs by about 2.8 percent compared to traditional builds. That might sound small, but across thousands of homes, the savings become massive.

Plus, timber has the added benefit of being more sustainable, locking in carbon rather than releasing it like concrete production does.

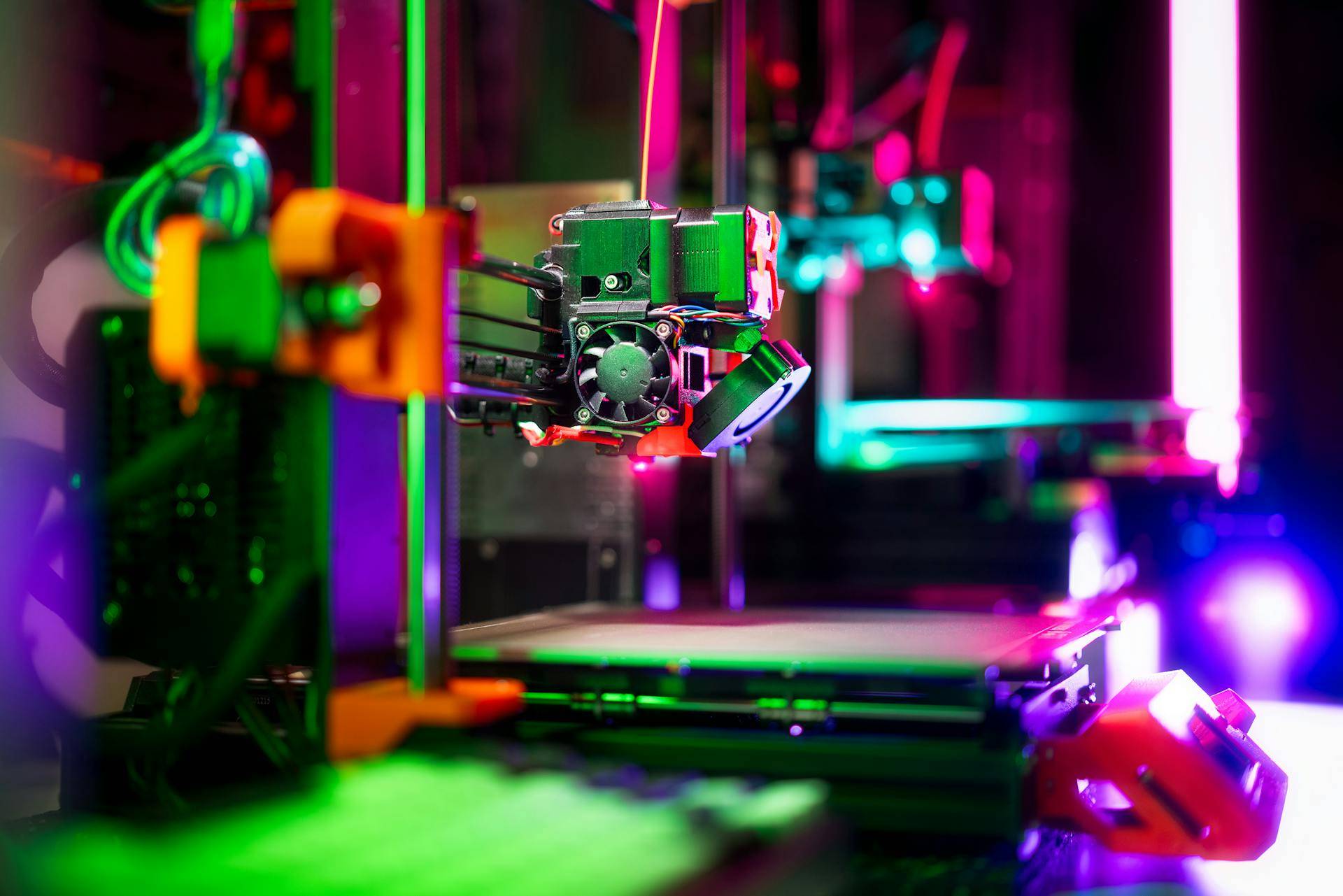

Robots on the Factory Floor

Here’s where things get really futuristic. Instead of bricklayers painstakingly stacking walls on-site, robotics-powered factories are producing precision-cut timber frames.

Machines handle everything from measuring to cutting, ensuring consistency and speed that humans simply can’t match.

Once the panels are ready, they’re shipped to the construction site where they’re assembled like giant Lego pieces. This blend of automation and prefab efficiency means houses can rise in weeks rather than months.

Breaking Down Safety Concerns

Of course, there’s always hesitation when a new method challenges tradition. Timber, especially in high-density housing, used to raise eyebrows over fire safety.

But recent regulation updates and advances in fire-resistant treatments are changing perceptions.

Policymakers and inspectors are finally recognizing that modern timber systems can be just as safe, if not safer, than masonry when properly designed. This shift in regulations has opened the door for widespread adoption.

Big Players Betting on Prefab

Some of the UK’s largest developers are putting serious weight behind this movement. Bellway, Vistry, and Taylor Wimpey—names that dominate the housing market—are all expanding into prefab timber systems.

Their involvement signals more than just curiosity; it’s a commitment to reshaping how homes are built. When the industry’s giants invest, you know a trend is here to stay.

Faster Builds, Greener Cities

The advantages stretch beyond cost. Timber prefab construction means fewer trucks clogging roads, less noise and dust in neighborhoods, and a dramatically reduced carbon footprint.

For cities under pressure to grow sustainably, this approach checks all the right boxes. Imagine walking through a newly built community that rose almost overnight—sleek, modern homes that are affordable, sustainable, and designed for the future. That’s no longer a fantasy.

What This Means for the Future of Living

If the UK proves that robotics-powered timber-frame construction works on a large scale, it could set a model for the rest of the world.

Other countries grappling with affordability and labor shortages may look to Britain’s experiment as the blueprint. Homes that are cheaper, safer, and greener? That’s not just a construction revolution—it’s a lifestyle revolution.